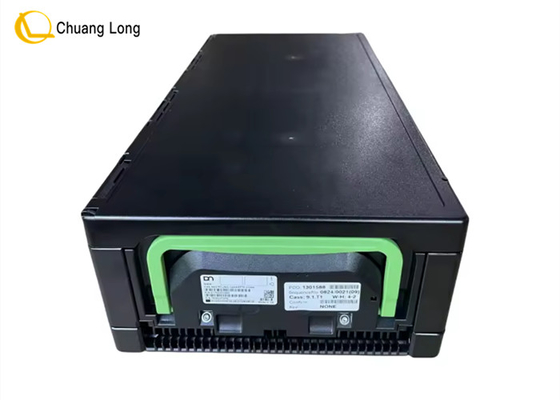

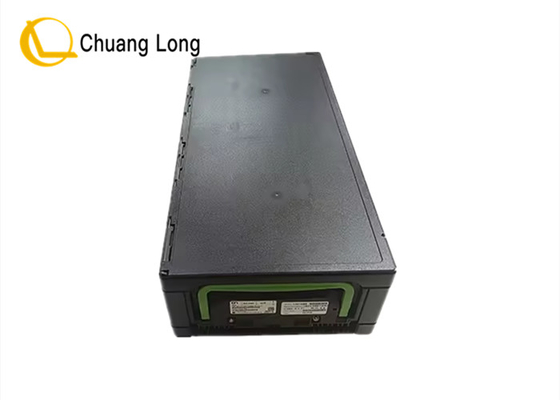

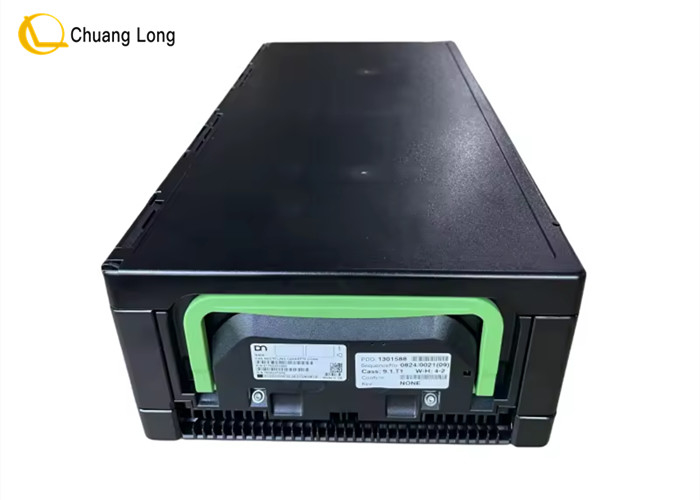

Diebold atm machine parts DN200 Cas Recycling cassette conv 1750301000 01750301000

Description

Product name

Diebold atm machine parts DN200 Cas Recycling cassette conv

P/N

1750301000 01750301000

Brand

Diebold DH200 DN200V

Keyword

ATM Machine Parts

Used in

Diebold ATM Machine

Delivery Time

1-7 Working Days

Relative products

| 445-0591578 |

MIB Timing Disk |

| 445-0632941 |

NCR 36T/26G |

| 445-0587795 |

NCR 36T-44T Gear |

| 998-0235885 |

NCR Roller narrow |

| 998-0235658 |

Main reading head TR-2 NCR |

| 998-0235654 |

NCR pre-reading head |

| 998-0879553 |

NCR 5886 Receipt Printer Belt (87) |

| 009-0007773 |

Retaining ring for plastic bearing MULTI M4 (presenter 4G / NID / MIB) |

| 009-0002367 |

Thrust washer quick-detachable DIN 6799 M5 (5; 4.11; 11.3; 0.7) |

| 009-0002370 |

Thrust washer DIN 6799 M8 (8; 6.52; 16.3; 1) |

| 1750267132 |

Wincor TP28 Printer |

| 1750267132 |

Wincor TP28 Printer |

| S7000000227 |

Hyosung CRM CSM |

| S5677000018 |

Hyosung printer head |

| 4520000297 |

Hyosung reverse roller |

| 4520000013 |

Hyosung feed Roller |

| 49-249440-768A |

Diebold EPP 7 BSC LGE,ST,STL,HTR,ENG |

| 49-216681-745E |

Diebold EPP5 PCI |

| 1750262084 |

Wincor PC Core 5G i5-4570/4GB/500HDD |

| 1750255914 |

Wincor EPPV7 English |

| 998-0235676 |

NCR Card reader roller thin |

| 998-0235677 |

NCR Card reader roller thick |

Company Information:

Welcome to Beijing Chuanglong, where precision meets professionalism in our state-of-the-art production line. Specializing in the intricate task of fixing and assembling parts for ATM accessories, we stand at the forefront of technical excellence. Our production line is not just a series of processes; it's where skilled craftsmanship and advanced technology converge to ensure each component meets the highest standards of quality and reliability.

Our team of experts is adept at handling the complexities involved in assembling and repairing ATM parts, making our production line a hub of innovation and efficiency. From the smallest screw to the most critical mechanical component, every part is treated with utmost care and precision, reflecting our dedication to perfection.

At Beijing Chuanglong, we understand that the integrity of an ATM machine hinges on the flawless functionality of its parts. Therefore, our production line is equipped with cutting-edge tools and technology, enabling us to fix and assemble parts with unparalleled accuracy. This meticulous approach not only enhances the durability and performance of our products but also reinforces the trust our customers place in us as a global leader in ATM accessory manufacturing.

Join us in experiencing the excellence of a production line where professional fixing and assembly are not just tasks but art forms, ensuring that every product from [Your Company Name] sets a benchmark in the industry.

FAQ

Q1. What’s the condition of your product?

A: Generally we can provide 4 conditions: new original, new generic,original used and original refurbished.

Q2.Does your product have a warranty?

A: Yes. Every product have a warranty, normally it is 3 months.

Q3. Do you have your own factory?

A: Yes. We have our factory, located in Zhuhai. We do the refurbishment by ourselves and We can build the molds and fixtures.

Q4. What’s the lead time of your product?

A: Normally it is 1-7 days after payment. The lead time is related to the quantity you ordered.

Advantage:

21 Years Experience in ATM Parts and Machines

10+ ATM Brands: NCR,Wincor, Diebold, Hyosung, NMD

9000+ Kinds Of ATM Products

100+ Oversea Clients From 30+ Countries

SAP+OA+Barcode Management System

US 200,000 Regular Stock ,1~14 Days Lead Time

Reasonable Prices ,Flexible Payment Methods

90 Days Warranty,Sample Provide

Strict Quality Control ,Professional Technical Team

Save 20%~30% Cost By Factory Customized Production

Production line:

We have well-trained and experienced hardware maintenance engineers that specialize in maintaining PCBs and modules. While ensuring ATMs to operate at high efficiency, we strive for passing savings onto our customers and keeping their maintenance costs at minimum. Our large in-stock inventory will certainly help in reducing lead time as well.

Our strong and innovative research and development team keep developing and improving new products made us ahead in banking equipment field. We intented to produce our own automatic teller machine in one year time.

Our Team:

| 1. |

Research and Development Department |

| 2. |

Production Department |

| 3. |

Sales Department |

| 4. |

Technical Department |

| 5. |

Management Department |

| 6. |

After-service Department |

Packing & Shipping :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!